|

250 Three in One NG OK Buffer Machine |

|

1) External dimensions:L1500*W1250*H1200mm |

|

2)special aluminum profile guide and special thousand bird plastic chain |

|

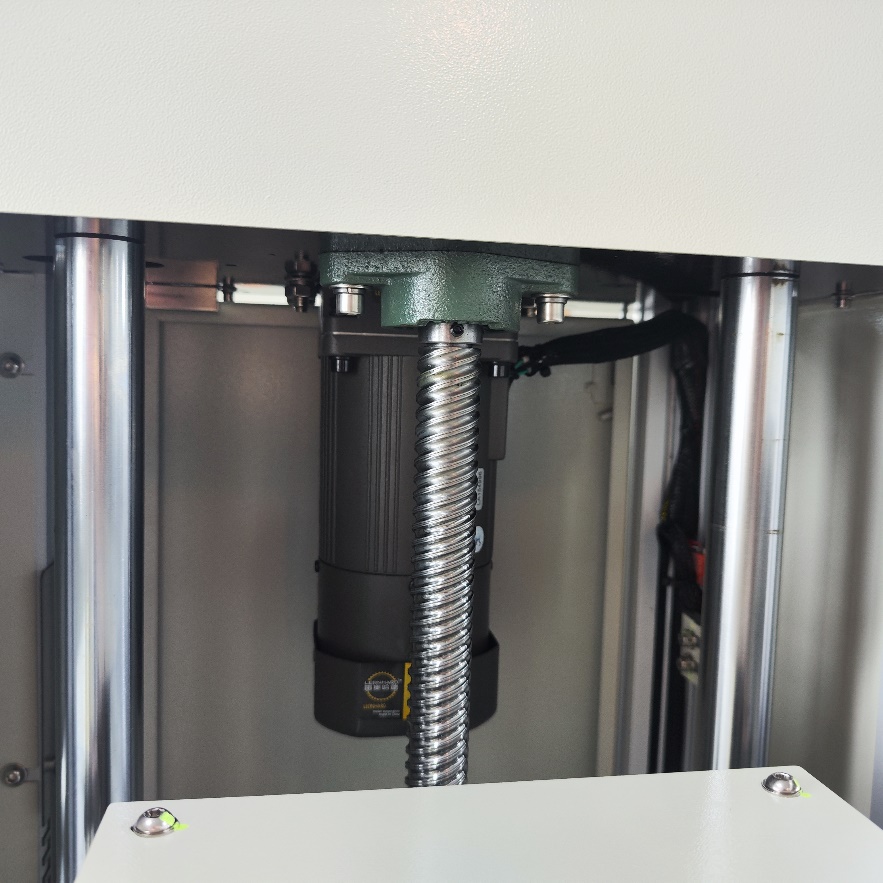

3)120W brake motor drive ball screw to make Magazine step up and down |

|

4) Magazine specification (L)355*(W)320*(H)565mm |

|

5) PCB specification max:(L)350*(W)250mm |

|

6)Transport Direction: left to right/right to left |

|

7)The pitch selection for the lifting platform is 10, 20, 30, 40 |

|

8)PCB transmission height :H=900±20 |

|

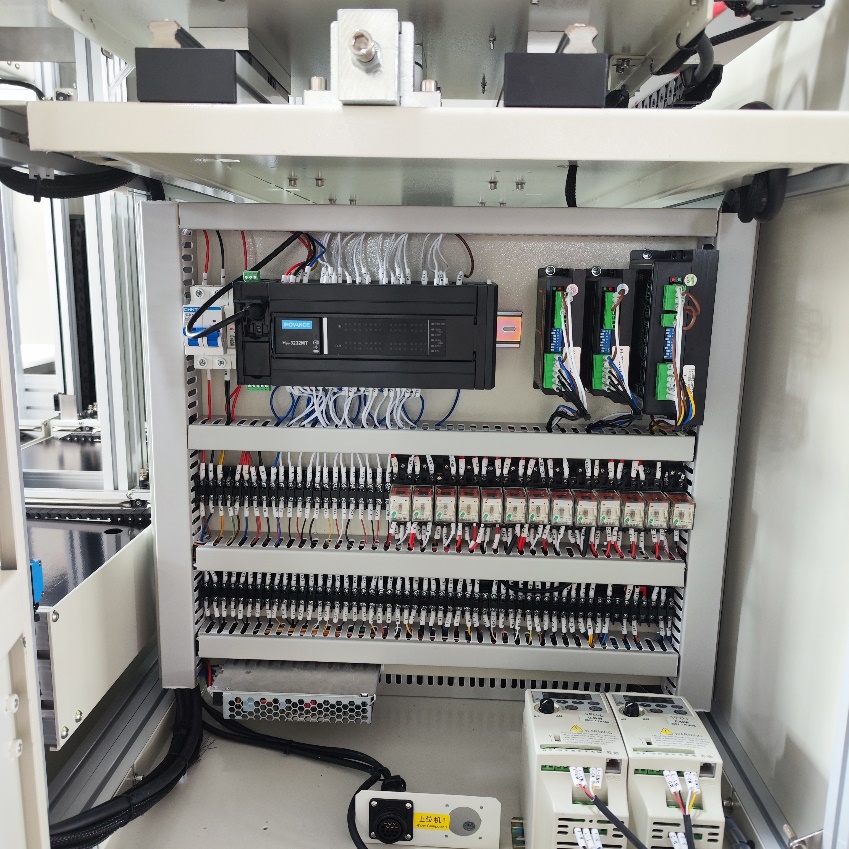

9)Mitsubishi PLC programmable controller control |

|

10)Equipped with automatic board loading, unloading, and buffer functions |

|

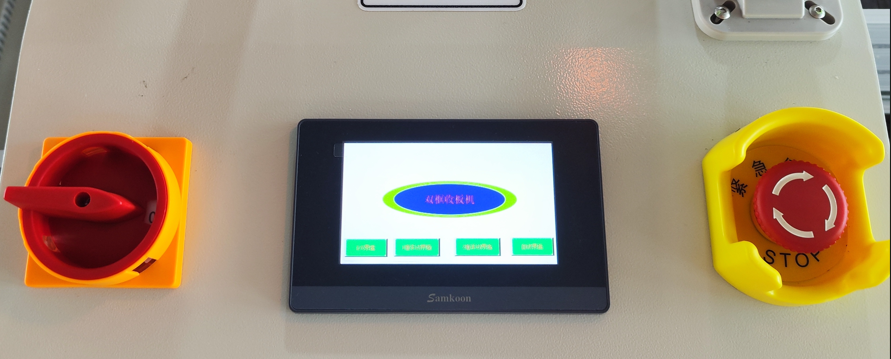

11)The operation control panel is a display control touch screen |

|

12)Yadeke for pneumatic components (adjusting the position of the push plate cylinder with a screw) |

|

13)Distinguish between good and bad boards; |

|

14) can modify the storage status of each layer in the material box, |

|

"NG", "OK", and "None" can be switched between each other; |

|

15) The storage mode can be selected as "direct" (only on the first layer of the material box for entering and exiting the board) |

|

Or "buffer" (each layer can store boards) |

|

Or "NG" (alarm upon entering an NG board) mode; |

|

16) When the PCB in the storage box is full, there are spare storage boxes that can be replaced with each other |

|

17)With cooling function |

|

18) Support removing the entire box of defective products at once |

|

19)power:220V 50HZ,air source:0.4-0.6MPa |

|

20)full load storage:50PCS |

|

21)a set of electric control box. |

Control System:

True color full touch screen control, program settings, convenient and fast, stable performance, with automatic and manual operation interfaces that can be switched according to needs.

Warning System

Built in detailed fault retrieval function and safety detection system, with sound and light alarms and text prompts for handling solutions in case of abnormalities, making it convenient to handle.

Eevating system:Using ball screws and high carbon steel columns, it has low noise, low vibration, and precise positioning.

Sensor system:

The Panasonic Omron sensor is sensitive to incoming and outgoing board sensing, making the pre production operation smoother.

Electrical Control System:

Independently developed electronic control system, with stable program and safe operation.

Signal:

Standard SMEMA signal line interface, can be connected and used with other automation equipment.

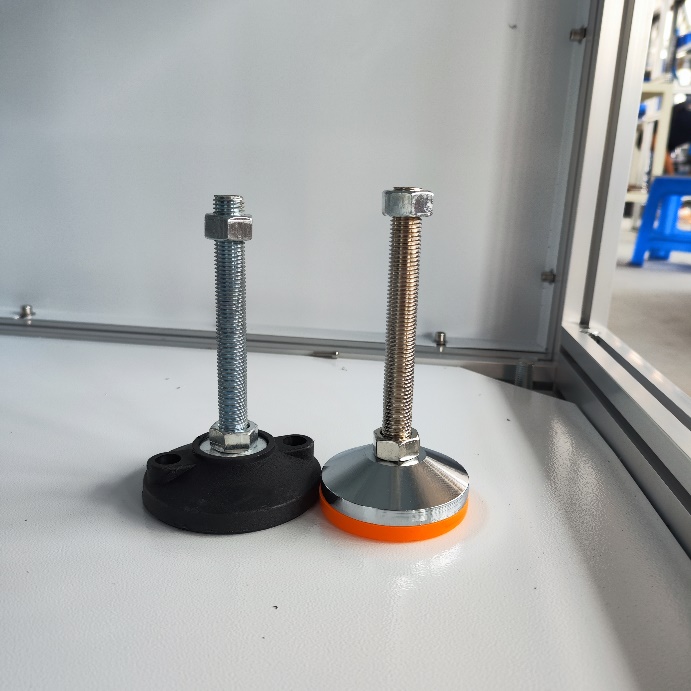

Goblet:

Adjustable height goblet, can adjust the machine height according to the production line height.

Profile frame:

Aluminum profiles, customized thickened sheet metal, machine is more stable, sturdy and durable, cold plate powder spraying, uniform spraying, and more beautiful. Colors can be specified according to customer requirements.