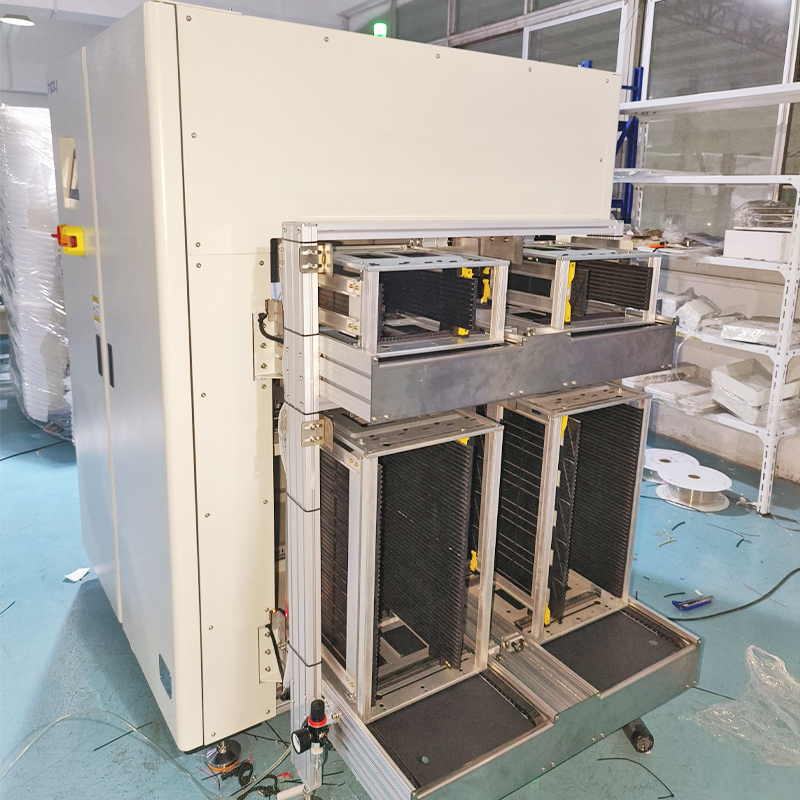

SMT Double track pcb 250NGOK Unloader machine

1. Parameter

|

SMT Double track pcb 250NGOK Unloader machine |

|

1) external dimensions:L1690*W1270*H1665mm |

|

2) Special national standard frosted aluminum profile guide railand specialthousand-bird plastic chain |

|

3)Huichuan servo motor drives the ball screw to make the Magazine step up and down |

|

4) Yadeke pneumatic clamp structure. |

|

5) Two sets of 0.6M lona transplantable push plates are attachea |

|

6) The specification of Magazine is (W)320*(L)355*(H)570mm |

|

7) PCB specification L330*W250 |

|

8) Directions: right to left/left to right |

|

9)Liftplatform pitchselectionis 10,20,30,40,50 |

|

10) PanasonicPLCprogrammable controller control |

|

11)It has the function of separating good and bad plates with its own double track. The material box is divided into upper and lower layers, with 50 OK plates in the lower layer and 10 NG plates in the upper layer. |

|

12)The operation control panel is a Taiwan-made joint-venture display and control touch screen |

|

13) power:uniphase 220V 50HZ |

|

14) air source:0.4-0.6MPa |

|

15) a set of electric control box |

|

16) Panasonic ,Omron Optoelectronics, Mingwei Power Supply, Schneider Relay. |

2. Product Introduction:

Introducing the SMT Double track pcb 250NGOK Unloader machine, a cutting-edge solution designed to streamline material unloading processes while efficiently sorting products into different categories based on their quality. This innovative machine features dual tracks for simultaneous unloading and sorting, maximizing throughput and productivity in manufacturing and logistics operations. Whether you're in the automotive industry, electronics manufacturing, or distribution center management, the SMT Double track pcb 250NGOK Unloader machine ensures seamless material flow and quality control for optimal operational efficiency.